PROJECT

Solar Fruit Dryer Using Sun Dry Technology

Nelson Annatara Salifu

DR Hilla Liman Technical University

P.O. Box 553, Wa, UW/R

Telephone number: +233 242090915

Corresponding email:

salifunelson800@gmail.com

ABSTRACT

In a bid to address various socio-economic challenges, students from Technical Universities in Ghana proposed a range of cutting-edge solutions. From a Biometric Health Identification System to a solar fruit dryer, and from sustainable paper packaging to a portable renewable power generation system, these innovations aim to transform industries and improve lives. In the healthcare sector, the Biometric Health Identification System and the MedEase app seek to enhance patient identification, data management, and supply chain efficiency. Meanwhile, the PECTA Blood Warmer promises to revolutionize blood transfusion safety. In agriculture, the solar fruit dryer and the improved Plastic Film Mulch Laying Implement aim to reduce post-harvest losses and promote sustainable food production. In energy, the IoT and AI Energy Management System and the portable renewable power generation system seek to optimize energy consumption and reduce reliance on non-renewable sources. Finally, in construction, sustainable flood resilient homes and the use of plastic waste as a binding agent for producing roof and wall tiles offer innovative solutions to environmental challenges.

These pioneering projects have the potential to drive positive change in Ghana and beyond.

Introduction

Preservation of food stuffs is necessary in Ghana because production is mainly seasonal whereas consumption is year-round.

Preservation of food stuffs is necessary in Ghana because production is mainly seasonal whereas consumption is year-round.

Preservation of vegetables and other agricultural products are essential for long time storage without further deterioration in the quality of the product. Several process technologies have been employed on an industrial scale to preserve agricultural products; the major ones are canning, freezing, and dehydration (Sridhar et al., 2021). Among these, drying is especially suited for developing countries with poorly established low temperature and thermal processing facilities (Boateng, 2024). Post-harvest losses of fresh fruits are aggravated by the recurring failure of most farmers to adequately process their fresh fruits to prolong shelf life for future consumption and marketing during the season of abundance for the off-season (Binge et al., 2023). For instance, there is a high bumper harvest of fresh mango fruits every year, however, due to a lack of preservation facilities 20% to 50% of these produce are lost and scarce during the lean season (Omari et al., 2020) (see Figure 1).

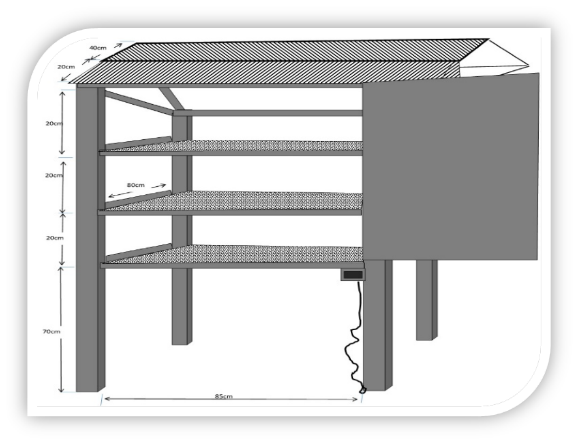

This sun dry technology, using a solar dryer, seeks to develop a drying facility for ensuring the shelf life of fresh fruits into flakes. The dryer is built by locally available, biologically degradable, low-cost materials. The dryer consists of a plastic material used as the roofing, an elevated four-squared frame, and plywood as the insulator, trays, sawdust, a drying chamber, and a vent pipe with the inner painted with black paint to trap radiations/heat from the sun with the ability to maintain temperature during day and night to facilitate the drying process in the system. Drying processes play an important role in the preservation of agricultural products. 'Solar drying' in the context of this technical brief, refers to methods of using the sun's energy for drying, but excludes open air 'sun drying’. The constructed dryer can dry 70-80% of agricultural products, such as cereals, tubers, fruits, vegetables, herbs, etc., to increase their shelf life and reduce postharvest loss. The potential beneficiaries of this technology are households, fruit and vegetable processors, and large corporations.

1. APPROACH AND UNIQUENESS

The main components of the solar dryer are: drying chamber, rack and trays, chimney with removable cove. The materials used for the construction includes the following; 2” by 4” locally available boards, aluminum wire mesh, plywood, saw dust, carpenter white glue, nails of different types transparent Plastic Sheet and black paint., as shown in Figure 2

Figure 1: Schematic sketch of the solar dryer

Figure 3: Constructed solar dryer

2. RESULTS AND CONTRIBUTIONS

The constructed solar dryer consists of two major compartments or chambers being integrated together. In this solar dryer constructed, the greenhouse effect and thermos siphon principles are the theoretical basis. The hot air acts as the drying medium, it extracts and conveys the moisture from the fruits to the atmosphere under natural convection. see Figure 3).