PROJECT

Design and Fabrication of an improved fully mounted Prototype Plastic Film Mulch Laying Implement

TEAM MEMBERS

EXHIBITORS

- Arhin Stephen arhinstephen505@gmail.com

- Ezekiel Teye Odonkor ezekielteye7@gmail

SUPERVISORS

- Ing. Samuel Kojo Ahorsu shorsu 0249739239

sahorsu@yahoo.com - Dr. Mensah-Brako Bismark

0597263253

mensahbrakobismark@ymail.com - Ing. Pearl Nutifafa Yakanu

0547698080

nutipearl6@gmail.com

INSTITUTION

- Dept of Agricultural Engineering

Ho Technical University

Box HP217 Ho, Ghana

ABSTRACT

In a bid to address various socio-economic challenges, students from Technical Universities in Ghana proposed a range of cutting-edge solutions. From a Biometric Health Identification System to a solar fruit dryer, and from sustainable paper packaging to a portable renewable power generation system, these innovations aim to transform industries and improve lives. In the healthcare sector, the Biometric Health Identification System and the MedEase app seek to enhance patient identification, data management, and supply chain efficiency. Meanwhile, the PECTA Blood Warmer promises to revolutionize blood transfusion safety. In agriculture, the solar fruit dryer and the improved Plastic Film Mulch Laying Implement aim to reduce post-harvest losses and promote sustainable food production. In energy, the IoT and AI Energy Management System and the portable renewable power generation system seek to optimize energy consumption and reduce reliance on non-renewable sources. Finally, in construction, sustainable flood resilient homes and the use of plastic waste as a binding agent for producing roof and wall tiles offer innovative solutions to environmental challenges.

These pioneering projects have the potential to drive positive change in Ghana and beyond.

Design and Fabrication of an improved fully mounted Prototype Plastic Film Mulch Laying Implement

Global warming, late onset and early cessation of rainfall pattern and adapted land use systems have led to moisture stress affecting sustainable agricultural systems. Mulching techniques help to control soil temperature, conserve moisture, reduce weed growth and improve soil fertility, thereby promoting sustainable food production systems and enhancing food security. Plastic mulches significantly influence plant growth and yield by altering soil microclimate. They increase fruit and vegetable yields by enhancing soil temperature, conserving moisture, and reducing pesticide application. Small-scale farmers often encounter difficulties when it comes to procuring or renting CAT II plastic film mulch laying equipment and CAT II tractors due to limited availability and dependence on manual labor. This situation leads to inefficiency, increased labor expenses, and reduced productivity among several farmers. While a power-operated machine is cost-effective, it requires specific conditions for optimal performance, including large land holdings, uniform terrain, access to roads for transporting the machinery to the field, and sufficient power sources to operate the mulching equipment. This fabricated plastic film mulch laying equipment has been created to fit either a category I or II hitch pin. This advancement in plastic film mulch laying implement will contribute to knowledge in the field and mechanization of plastic film mulch laying in Ghana as well as the other parts of the world

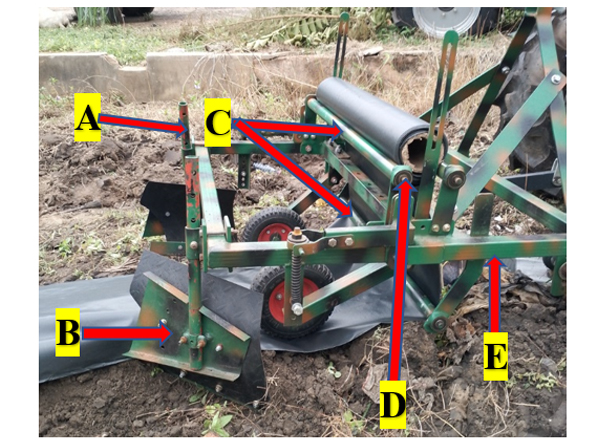

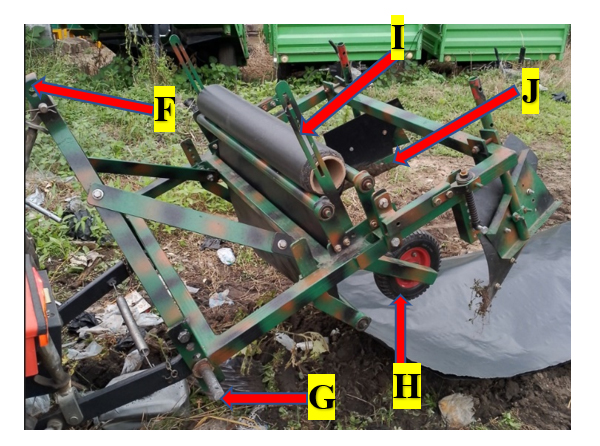

Fabricated Plastic Film Mulch Laying Implement with its main components: A-Mouldboard Depth Gauge, B- Mouldboard, C- Rollers, D- Bearing, E- Main Frame, F- Top Hitch Mast, G- CAT I & II Hitch Pin, H- Pressing Wheel, I- Plastic Film Mulch Support and J- Share.

Fabricated Plastic Film Mulch Laying Implement with its main components: A-Mouldboard Depth Gauge, B- Mouldboard, C- Rollers, D- Bearing, E- Main Frame, F- Top Hitch Mast, G- CAT I & II Hitch Pin, H- Pressing Wheel, I- Plastic Film Mulch Support and J- Share.